While technology continues to march us forward, good ol’ steam remains critical to production in many industries including chemical processing, energy generation, food & beverage, building heat, and pharmaceuticals to name just a few. The process for making steam may not have changed much over the years, but like almost all other components of production the cost to produce it keeps going up. When costs are going up, the focus on efficiency is greater, creating a greater emphasis on accurate flow data.

There are several technologies available for measuring steam flows, but in our experience, we mostly see turbine, vortex and differential pressure across an orifice plate in the field. DP technology is the legacy technology for steam flows and is far and away the most common in older installations. All three technologies can measure both steam and temperature to calculate mass flow. With all the pressure variations that can occur in steam flows, simple volumetric measurement is not sufficient for accurate steam flow measurement.

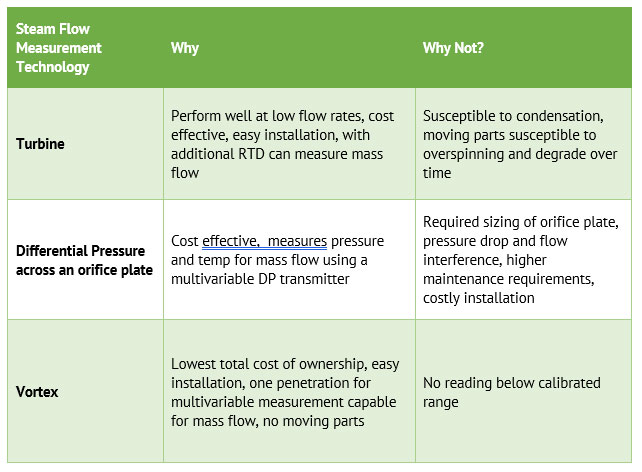

While all three technologies have proven effective over time, vortex technology has become the ideal choice for measuring steam flows. Here is a simple overview of each technology’s pluses and minuses:

From an up-front cost perspective turbine meters are the least expensive option with DP being the most expensive (when you add temp sensor to calculate mass flow and installation costs) while vortex falls roughly in the middle. However, when you start including all the maintenance costs associated with DP and turbine technologies, the total cost of ownership for vortex holds relatively steady while DP and turbine rise significantly over time. As dirt and scale build up in steam lines, turbines and DP impulse lines begin to clog while orifice plates begin to degrade reducing both accuracy and life expectancy. Steam line blowdowns take their toll on turbines and require the isolation of the DP transmitter and cleaning of impulse lines. With no moving parts or impulse lines, vortex meters require minimal maintenance.

From a turndown perspective, turbine meters typically have the widest turndown range with mass flow accuracy of +/-2.0%. Vortex meters also have a very wide turn down range of roughly 30:1 with a similar mass flow accuracy of +/- 2% and better accuracy of +/-1.0% for volumetric flow. DP with orifice plate typically has the narrowest turndown in the range of 10:1 with a similar accuracy as vortex. It is worth noting though, that while their accuracy slips significantly, both turbine and DP technologies can measure in low flow conditions with reduced accuracy. For flow rates below a vortex meters calibrated range, readings become erratic.

Vortex flow technology has been around for a long time and it was not until Sierra Instruments introduced the multivariable mass vortex flowmeter in 1997 that vortex became a reliable option for steam flows. As the demand for production efficiency increases and older technologies are due for replacement, in our opinion, vortex technology has become the best option for steam flow measurements because of its higher accuracy, better reliability, lower installation and maintenance costs and lowest total cost of ownership over the life of the meter.

Learn More:

Sierra’s InnovaMass 240i Inline and 241i Insertion Vortex Meters (https://www.sierrainstruments.com/products/steam)

Suppliers

Products

Sierra InnovaMass® 240i Inline Meter

Sierra’s next generation inline vortex meter is ideal for saturated and superheated steam, gas and liquid applications. Able to measure both mass and volumetric flow rates, this one meter is multivariable for 5 measurements.